Types of Water Pumps

There is a diverse selection of water pumps available on the market today to cater to a wide range of uses and requirements. Find out the numerous applications of water pumps here. This including how they are usable in the agricultural sector. For the management of waste, as a device for flood control, and in the industrial sector. Pumping water is a fundamental and useful technique. It is significantly more useful than scooping it up with one’s hands. Or lifting it in a bucket that is held by one’s hand.

What is a water pump?

A water pump is a piece of electromechanical machinery that is applicable to raise the water’s pressure in order to transport the water from one location to another. The supply of water for municipal, industrial, agricultural, and domestic needs is ensured by the employment of contemporary water pumps in many parts of the world.

In sewage treatment plants, water pumps are also employed. They help to transfer the wastewater around the facility. Electricity is the power source that is utilized to operate most modern water pumps. However, other power sources, such as diesel or gasoline engines, are also sometimes used. Solar panels have the potential to be utilized to generate enough electricity to power smaller pumps in more remote locations, such as desert areas.

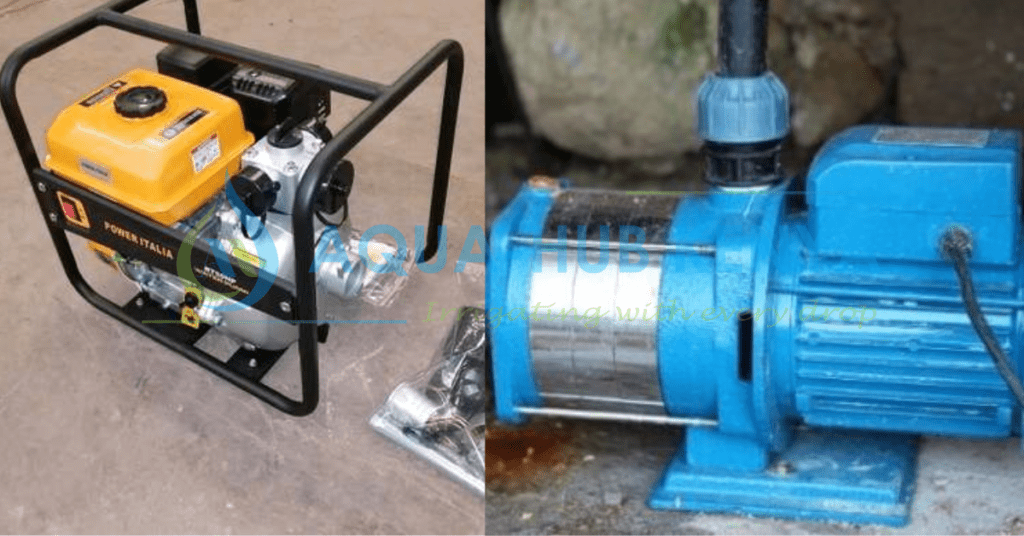

What are the types of water pumps?

There are several distinct varieties of water pumps. Such as centrifugal pumps and positive displacement pumps. Which, despite their dissimilar modes of operation, are both capable of delivering the same level of service. Given that we are the market leaders in water pumps, you can rest assured that you are purchasing the highest quality product available in Kenya. The fundamental idea behind a water pump is to make use of a motor in order to transform rotational energy. Or kinetic energy into energy that can be used to move fluid or to facilitate flow of fluid (hydrodynamic energy).

Centrifugal Pump

The centrifugal pumps have a component called an impeller. This allows fluid to enter via the revolving part of the pump. Then be pushed out through the impeller’s tips by centrifugal force. This procedure results in an increase in the fluid’s velocity as well as its pressure. It further drives the fluid toward the outlet of the pump. The submersible pump is an example of a centrifugal pump type.

It is a rotational machine in which an impeller rotates inside a casing. Sucks in the liquid at its center, and throws out the liquid due to centrifugal force via an opening at the side of the casing. The centrifugal water pump is most typically used for agricultural reasons.

Reciprocating pumps

They are positive displacement pumps that have a cavity that is expanding on the suction side of the machine and a cavity that is decreasing on the discharge side of the machine. The expansion cavity is positioned on the suction side. Each cycle of the water pump has a constant volume. Regardless of the pressure that is being applied or the size of the pump head that is being utilized. This is because the water pump operates by alternatively filling the cavity and then displacing the fluid.

Submersible pumps

The Electric Submersible Pumping Principle governs the operation of submersible pumps (ESP). By lowering the flow pressure, the submersible pump is able to lessen the pressure at the bottom of its shaft. Because oil wells, for example, often have very deep wells, the ESP system’s motor is built to withstand high temperatures (up to 300 degrees Fahrenheit) and high pressures.

Deep motors can be expensive to run due to the need for specific electricity lines. However, modern innovations have seen the advent of coiled tubing umbilical. Other submersible pumps use a lot more electricity, and the pump’s tight tolerances don’t allow it to work well when it comes to sand and other solid particles.