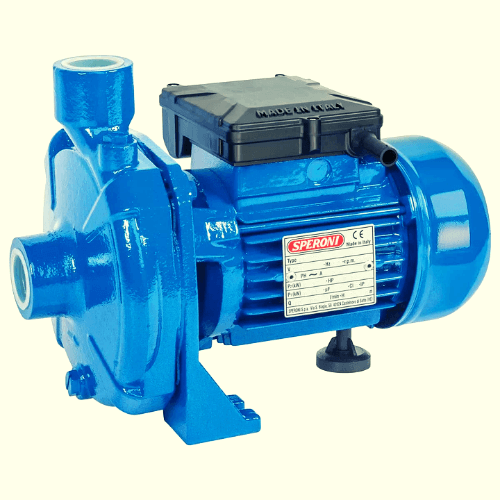

High Pressure Water Pump

A high pressure water pump is a device that increases the pressure of water. It does this from a low-pressure source to a higher-pressure output. These pumps are used in a variety of applications, including irrigation systems, firefighting, industrial cleaning, and oil and gas production. High-pressure water pumps play a crucial role in various industrial and agricultural applications. Helping to increase the pressure of water for various tasks and processes. We have the different types of high pressure water pumps.

What is a high pressure water pump?

A high-pressure water pump is a type of pump that is designed to increase the pressure of water. It does this from a low-pressure source to a higher-pressure output. These pumps are commonly used in various applications such as irrigation systems, firefighting, industrial cleaning, and oil and gas production. High-pressure water pumps use mechanical or hydraulic energy to compress the water, increasing its pressure.

What are the types of high pressure water pumps?

There are several types of high-pressure water pumps, including:

- Centrifugal Pumps: Centrifugal pumps use an impeller to increase water pressure by converting mechanical energy into hydraulic energy. They are the most common type of high-pressure water pump. They are also widely used in various applications such as irrigation, firefighting, and industrial cleaning.

- Positive Displacement Pumps: Positive displacement pumps work by trapping a fixed amount of water. Then forcing it through a small outlet. This compression of the water increases its pressure. Examples of positive displacement pumps include reciprocating pumps and rotary pumps.

- Jet Pumps: Jet pumps use a high-speed stream of water to create a vacuum. This pulls water from a low-pressure source and increases its pressure. They are often used for deep well water pumping. And other applications where water has to be lifted from a great depth.

- Submersible Pumps: Submersible pumps are high-pressure water pumps that are designed to operate underwater. They are often used in wells, fountains, and other applications where water needs to be pumped from below the surface.

- Diaphragm Pumps: Diaphragm pumps use a flexible diaphragm to compress water and increase its pressure. They are often used in applications where the fluid being pumped is abrasive, corrosive, or contains particles.

Choosing the right type of high-pressure water pump will depend on the specific requirements of your application. Such as flow rate, pressure requirements, and the type of fluid being pumped. It is important to choose a pump that is appropriately sized. And designed for your application to ensure efficient and effective operation.

What are the factors to consider when choosing a high pressure water pump?

When choosing a high pressure water pump, there are several key factors that should be considered:

- Flow rate: The flow rate of the pump is important. This is, because it will determine how much water can be moved per unit of time. Consider the volume of water that you will need to pump. Then choose a pump that meets your flow rate requirements.

- Pressure rating: The pressure rating of the pump will determine the maximum amount of pressure that the pump can deliver. Make sure that the pump you choose has a pressure rating that is sufficient for your needs.

- Power source: High pressure water pumps can be powered by electricity, gasoline, or diesel. Consider the power source that is most convenient for you. Then choose a pump that is compatible with your chosen power source.

- Size and weight: High pressure water pumps can be quite heavy. Therefore, consider the size and weight of the pump when choosing one. Make sure that the pump is of a size and weight that you can easily move and handle.

- Material and construction: High pressure water pumps are often made of metal, such as steel or aluminum. They should be constructed in a way that makes them durable and long-lasting. Consider the material and construction of the pump when choosing one.

- Cost: High pressure water pumps can vary in price, so consider your budget when choosing one. Look for a pump that offers good value for the money, and that meets all of your other requirements.

- Brand reputation: Consider the brand reputation of the pump when choosing one. Look for a brand that is known for producing high-quality pumps. The one that has a good track record of customer satisfaction.

What is the use of high pressure water pump?

High pressure water pumps are used in a variety of applications where high pressure water is required. Some common uses of high pressure water pumps include:

- Industrial cleaning: High pressure water pumps are commonly used for industrial cleaning, as they are able to deliver high pressure water to remove dirt and grime from large surfaces.

- Agriculture: High pressure water pumps are used in agriculture for irrigation and for cleaning livestock pens, barns, and other agricultural structures.

- Firefighting: High pressure water pumps are used in firefighting to deliver high pressure water to put out fires.

- Pressure washing: High pressure water pumps are used in pressure washing for cleaning large surfaces, such as buildings, bridges, and ships.

- Water treatment: High pressure water pumps are used in water treatment to pump water from one location to another, and to deliver high pressure water to water treatment systems.

- Mining: High pressure water pumps are used in mining to deliver water to underground mines and to power hydraulic equipment.

- Construction: High pressure water pumps are used in construction to deliver high pressure water to clean and prepare construction sites, and to power concrete pumps.

- Car washing: High pressure water pumps are used in car washing to deliver high pressure water to clean cars, trucks, and other vehicles.

In general, high pressure water pumps are useful in any application where high pressure water is required. They can be used to deliver water to a variety of locations, and they can be used to power a wide range of equipment and systems.

How long can a pressure pump run continuously?

The length of time a pressure pump can run continuously depends on several factors, including the size and capacity of the pump, its material and construction, and the conditions under which it is operating. In general, most high pressure water pumps are designed to run continuously for several hours.

However, the actual length of time a pressure pump can run continuously will also depend on factors such as the temperature of the pump, the frequency of use, and the presence of any maintenance or operational issues. For example, if a pump is running continuously under high temperature conditions, it may have a shorter lifespan than if it were running under more moderate conditions.

It’s important to follow the manufacturer’s recommended maintenance schedule for your pump to ensure that it operates at its best for as long as possible. Additionally, it’s a good idea to monitor the performance of your pump regularly, and to take action if you notice any signs of wear or malfunction.

What causes high pressure pump failure?

High pressure water pump failure can be caused by a variety of factors, including:

- Overloading: Overloading the pump with too much water or with water that is too viscous can cause the pump to fail.

- Mechanical wear and tear: Mechanical wear and tear can occur over time, especially if the pump is used frequently or if it is used to pump abrasive materials.

- Corrosion: Corrosion can occur if the pump is exposed to harsh chemicals or if it is not properly maintained.

- Power failure: Power failures can cause the pump to shut down and can lead to pump failure over time.

- Leaks: Leaks in the pump or in the piping system can cause the pump to lose its prime and can lead to pump failure.

- Clogging: Clogging can occur if the pump is used to pump materials that can clog the pump or the piping system.

- Poor installation: Poor installation of the pump or the piping system can cause the pump to vibrate excessively, which can lead to pump failure over time.

- Lack of maintenance: Neglecting regular maintenance and inspections can lead to pump failure, as well as decreased efficiency and performance.

It’s important to identify the cause of a pump failure as soon as possible and to take appropriate action to prevent further damage and to prolong the life of the pump. Regular maintenance and inspections can help to reduce the risk of pump failure and can ensure that the pump operates at its best for as long as possible.