Blog

Dam Liners for Irrigation in Kenya

Using dam liners for irrigation in Kenya is one of the most effective ways for farmers to conserve water and grow crops throughout the year. Dam liners reduce seepage, protect stored water, and make irrigation more reliable even in dry places. When applied properly, they help farmers increase crop yields, enhance fertilizer efficiency, and manage water more effectively. This guide describes how to use dam liners for irrigation in Kenya step by step.

Takeaways

- Dam liners prevent seepage, allowing farmers to store more water.

- HDPE liners are the most durable for irrigation in East Africa.

- Proper installation and anchoring determine liner lifespan.

- Lined dams enable farmers to irrigate year-round, boosting yields.

- Dam liners make fertilizer use more efficient by supporting consistent irrigation.

- Regular maintenance prevents costly repair or early failure.

- Lined dams can also support fish farming, livestock watering, and domestic use.

Cost of Dam Liners for Irrigation in Kenya

|

Thickness |

Cost Per Square Metre |

|

0.3 mm |

180 |

|

0.5mm |

230 |

|

0.75mm |

320 |

|

1mm |

430 |

Why Water Storage Matters for Farmers in Kenya

Rainfall is Becoming Less Predictable

Rainfall pattern has become very unpredictable in recent years due to global warming effect. Dry spells extend longer than the normal expected duration, making it hard to grow crops consistently.

Reliable Water Enables Reliable Fertilizer Use

Fertilizer works best when plants receive consistent water. Too little water weakens plants; applying fertilizer without water often burns roots or leads to nutrient loss.

With a lined dam or pond, farmers can:

- Irrigate even during dry spells

- Time fertilizer application perfectly

- Ensure plants absorb nutrients fully

- Reduce fertilizer waste and leaching

Dam Liners for Irrigation Reduces Risk

Having stored water means farmers don’t gamble on rain. It allows planned irrigation schedules, staggered planting, and even multiple seasons per year.

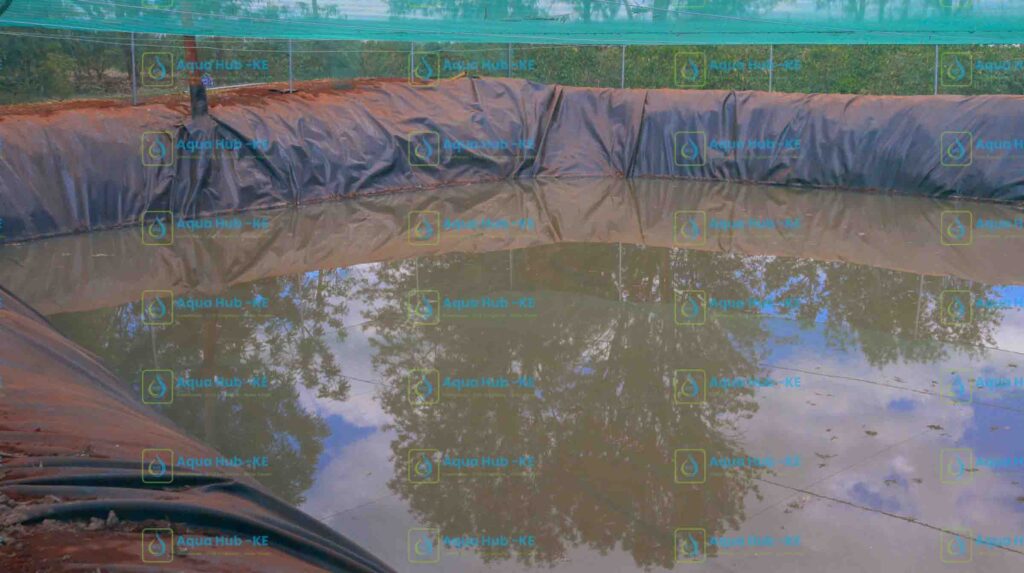

Dam Liners for Irrigation

Dam Liner roll

Dam Liners for irrigation are waterproof membranes used to cover the walls and bases of dams, reservoirs or ponds to prevent water seepage.

The most common dam liners in Kenya are made from High Density Polythene (HDPE) Material. The HDPE dam liner material is strong and highly durable compared to PVC or LDPE liners.

HDPE is the preferred choice for irrigation because it withstands sun, heavy water weight, and rough terrain.

Standard Thickness of Dam Liners for Irrigation

Common thicknesses include:

- 3 mm — small ponds

- 5 mm — medium water pans

- 75 mm — medium to large dams

- 1 mm — commercial or large reservoirs

Dam liners with high gauge are highly durable and resistant to puncture. For demanding projects such as sewage, chemical and industrial liquid containment high gauge is preferred.

Large irrigation or water storage reservoirs also need a high standard gauge dam liner, either 0.75 or 1 mm.

Why Use Dam Liners for Irrigation?

- Prevent Seepage (Save Every Drop)

The soil structure especially in arid and semi-arid parts of Kenya is sandy or porous in nature thus do not hold water long. A dam liner prevents seepage, ensuring stored water remains available for irrigation.

- Makes Irrigation Possible on Poor Soils

Even farmers with rocky, sandy, or unstable soils can successfully build a water pan by using liners to hold water securely.

- Enables Year-Round Farming

By using water collected in dam liners for irrigation, farmers can grow:

- Vegetables

- Capsicum

- Bananas

- Watermelons

- Onions

- Tomato

- Fodder Crops

With reliable water access for irrigation, you will manage to grow crops year-round.

- Versatile applications

Dam liners are not just used for irrigation water storage, the water could also be used for aquaculture, domestic and livestock needs.

Types of Dam Liners for Irrigation in Kenya

HDPE Dam Liners

Best for:

- Large farms

- Harsh soils

- Deep reservoirs

- Commercial aquaculture

Benefits:

- UV-resistant

- Strong tensile strength

- 15–25-year lifespan

- High puncture resistance

LDPE / LLDPE Liners

Best for:

- Small and medium ponds

- Farmers on tight budgets

- Areas with smooth soil

Benefits:

- Easy to install

- Affordable

- Flexible

PVC Liners

Used for:

- Temporary ponds

- Indoor tanks

- Shallow water pans

Downsides:

- Weaker under UV

- Not ideal for long-term storage

How to Choose the Right Dam Liner for Your Farm

Choosing the right liner ensures high efficiency, stable water supply and prevents costly repairs later.

- Assess Soil Type

Rocky soil → 1.0 mm HDPE

Sandy soil → 0.75 mm HDPE

Murram soil → 0.5 mm HDPE

- Consider the Reservoir Size

Small ponds → 0.5 mm

Mid-size dams → 0.75 mm

Large reservoirs → 1.0 mm

- Determine Water Demand

Estimate seasonal water use based on crops:

Vegetables: 6,000–12,000 L/day per acre

Bananas: 10,000–15,000 L/day per acre

Fodder: 5,000–8,000 L/day per acre

Your dam should be sized to store at least 60–90 days of water.

- Set Your Budget vs Lifespan Needs

Cheaper liners may save money now but cost more in repairs or early replacement.

How to Install Dam Liners for Irrigation

Dam Liners often fail to store water for a long time in your reservoir often due to poor installation. The right installation is as explained in the following steps.

Step 1: Choose the Right Site for a Dam

Select a location that:

- Is slightly lower elevation

- Has natural catchment

- Is close to crops

- Has stable soil

- Is accessible for site survey and installation.

For areas with frequent run-off, ensure the dam can capture maximum rainwater.

Step 2: Excavate the Dam

Use machinery or manual labor to excavate the water reservoir. Ensure the slopes are slanted 27–45° to enhance easier dam liner laying.

Create smooth, broad slopes rather than steep walls.

Step 3: Prepare the Base

Remove roots, stones, sticks and other sharp objects. Compact the soil to make the surface firm.

Step 4: Install Protective Underlay

Use a layer of fine sand or geotextile fabric on the floor to prevent uneven ground levels or punctures in case of rocky surface.

Step 5: Lay Out the Dam Liner

Unroll the liner carefully. While unrolling and spreading the dam liner, avoid dragging it on the ground surface. Make the liner to overlap at least 1 m at the edges to anchor the liner well.

For liners larger than 600 m², use at least four people to assist.

Step 6: Weld the Dam Liner

If your dam is large and requires more than one dam liner roll, they are attached using welding technique. Welding involves use a hot wedge machine to heat and seamless join two dam liner sheets.

Step 7: Anchor the Edges

Dig a trench 30cm deep and 30 cm wide around the dam.

Tuck in the extensive dam liner in the trench and bury the trenches with soil to ensure it holds it firmly. This way, the dam liner remains secure on the ground without removal by water or erosion. Heavy weights can also be used to hold the edges of the dam liner around the water reservoir.

Step 8: Pump Water to the Dam

Pump water gradually to the dam and check for leakage by monitoring the water level.

Maintenance and Care for Dam Liners

Regular Checks

Inspect your water reservoir for any punctures or leakages in the liner. Repair should be done immediately to avoid excessive water loss.

Control Vegetation

Remove large plants or shrubs growing near the dam. Tree roots can penetrate the liner over time.

Fence the Reservoir

Keep livestock and children away from the dam to prevent damage of the liner or accidents.

Prevent Algae Build-Up

Use barley straw or regularly clean your dam water to remove algae.

Monitor Water Levels

Allow a small amount of water to remain during dry months to avoid UV exposure.

Common Mistakes and How to Avoid Them

Poor Base Preparation

Sharp stones cause punctures.

Solution: Fully clear and compact.

Choosing the Wrong Gauge

Using 0.3 mm for a large dam leads to early failure.

Solution: Match thickness with size and soil.

Poor Welding or Joints

Poorly welded joints will result in heavy water loss due to leakages.

Solution: Ensure your dam liner installation is done by expert technician to ensure proper welding and zero leakage.

Cost vs Value: Are Dam Liners Worth It?

Upfront Costs

Prices vary by thickness and supplier:

- 5 mm: Affordable

- 75 mm: Mid-range

- 1 mm: Premium

Long-Term Value

Over 10–20 years, lined dams save money through:

- Reduced seepage

- Lower irrigation costs

- Higher yields

- Ability to grow high-value crops

- Fertigation compatibility

Tips for Farmers in Kenya

- Harvest rooftop water into lined dams. This can be done using gutters

- Choose HDPE for long-term irrigation projects

- Train workers on liner handling to prevent accidental damage

- Use solar pumps to reduce energy costs

- Keep livestock away from the liner

- Use inlets and outlets with filters to maintain water quality.

Frequently Asked Questions (FAQs)

-

What is the best dam liner thickness for irrigation?

0.75 mm or 1.0 mm HDPE is the best choice.

-

Can dam liners be used for fishponds?

Yes. HDPE liners are commonly used for tilapia and catfish ponds.

-

How long does a dam liner last?

HDPE liners last 10–25 years with proper installation.

-

Do dam liners require a protective underlay?

Not always, but it is highly recommended for rocky soils.

-

What is the cost of a dam liner in Kenya?

KES 150 to KES 450 per square meter.

-

How thick is a dam liner?

dam liners have varrying thickness sizes of 0.3mm, 0.5mm, 0.75mm and 1mm. -

Are dam liners expensive?

They are cheaper than concrete tanks and offer better long-term value.

-

Can dam liners withstand UV exposure?

HDPE liners are UV-resistant and ideal for sun-heavy regions.

-

What crops benefit from dam liners the most?

Vegetables, bananas, onions, tomatoes, and fodder crops.

-

Can I use dam liner water for drip irrigation and fertigation?

Yes. this combination maximizes fertilizer efficiency and crop yields.