Blog

Solar Drying in Kenya : Excellent Preservation

Post-harvest losses is a huge challenge to seasonal small-scale farmers in Kenya. Large agricultural produce from fruits to essential grains faces risk of spoilage. This could result to national food security crisis if not mitigated. Solar drying in Kenya prevents post-harvest losses and enhances food security because it removes moisture that promote bacterial growth.

Solar dryers offer a sustainable, cost-effective and environment friendly way to preserve food and make it easier for value addition.

Want an effective solar dryer?

Call 0790719020

Solar Drying in Kenya: How Solar Dryers Work

While open-air sun drying exposes produce to contamination, dust, and slow drying, solar dryers in Kenya offer a controlled and hygienic environment. The working principle of solar dryers revolves around sunlight heat harnessing and moisture removal from produce through air circulation and convection.

Most solar dryers operate on one or a combination of two basic principles:

-

Trapping Heat

Transparent covers, often made of UV-stabilized polythene, allow sunlight to enter but prevent the heat from escaping. This makes the air inside the drying chamber hot enough to remove moisture from the crop products.

-

Dehydration by Convection

As air inside heats up, it becomes lighter and rises. This hot, dry air then circulates through the drying chamber, passing over the produce. The increased temperature lowers the relative humidity, boosting its capacity to absorb moisture from the food. In advanced dryers, fans force hot air circulation accelerating the drying process and ensuring uniformity.

Moist air is removed through the ventilation. the process of air heating, dehydration and moist air removal goes on.

Types of Solar Dryers in Kenya

Solar dryers come in various designs, catering to different scales of operation and budget considerations. They can generally be categorized into:

Simple or Natural Convection Solar Dryers

These are the simplest and affordable solar drying structures in Kenya. They rely solely on natural air circulation.

Design: Typically consist of a solar collector (black dam liner) and a drying chamber made of shelves for the produce. Air Vents at the bottom and top facilitate airflow. Smaller versions might resemble a wooden box with screened frames.

Working: Air enters the collector, heats up, rises through the drying chamber, absorbs moisture, and exits through top vents.

Suitability: Small-scale farmers, household use, and communities, offering a low-cost entry into solar drying.

Hybrid Solar Dryers or Forced Convection Dryers

These incorporate additional mechanisms, usually fans powered by solar panels or even a small battery, to actively circulate air.

- Design: Like passive dryers but with the addition of fans for enhanced airflow. Hybrid models might also include a backup heat source (e.g., biomass, charcoal, or electricity) for continuous drying during cloudy periods or at night.

- Working: Fans force hot air from the collector through the drying chamber, leading to faster and more uniform drying. The hybrid aspect ensures consistent operation regardless of solar availability.

- Ideal For: Commercial farmers and larger-scale dryers who require higher drying capacity, faster turnaround, and consistent product quality.

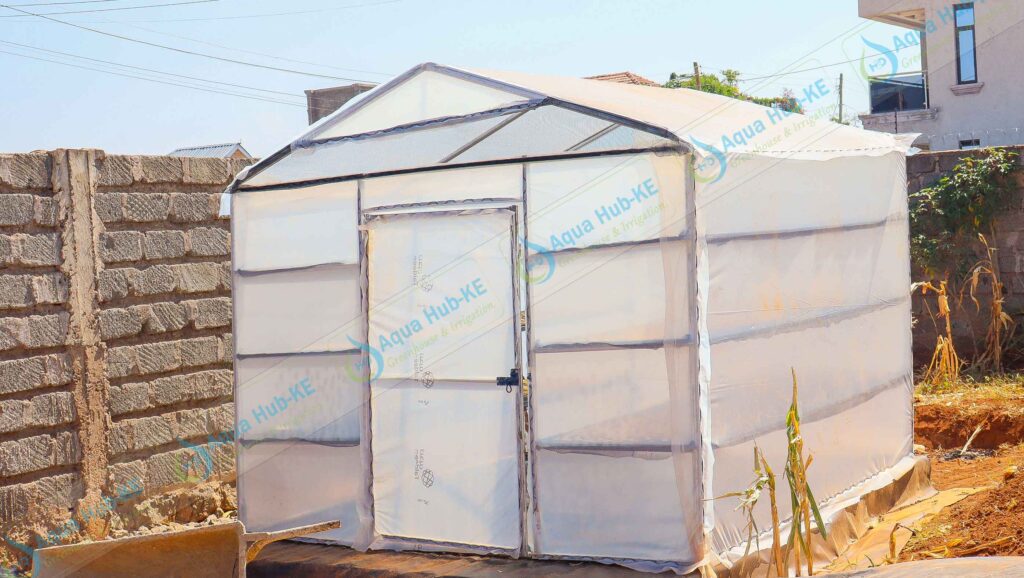

Tunnel Dryers

These are larger, semi-circular structures, often resembling a polytunnel greenhouse, where produce is laid out on trays along the length of the tunnel.

- Design: A polyhouse framed structure covered with UV-stabilized polythene. They are large enough for a person to enter and manage the produce.

- Working: Can operate passively or with forced convection, providing significant drying capacity for large volumes of produce.

- Ideal For: Industrial solar drying activities in Kenya. for example tea or coffee processing plants.

What Makes Solar Drying Efficient for Harvest Preservation?

- Temperature Control: Solar dryers enhance ideal drying temperatures for quick dehydration and prevent damage of nutrient or taste. Hybrid systems offer better temperature regulation.

- Airflow: Adequate and consistent airflow is paramount to carry away the released moisture. Forced convection dryers allow better airflow, preventing humidity build-up and ensuring even drying.

- Protection from Contamination: Enclosed designs protect produce from dust, insects, and bacteria, thus higher quality product compared to open-air drying.

- Reduced Drying Time: Compared to traditional sun drying, solar dryers can significantly reduce drying time, often by 40-50%. Hybrid dryers take 10-24 hours to dry the produce.

- Nutrient Retention: By temperature control, solar dryers preserve nutritional value of the produce.

Costs of Solar Drying in Kenya

The cost of solar dryers in Kenya varies widely depending on the type, size, and design of a solar dryer.

Small Scale Passive Dyers

Relatively inexpensive, with common sizes starting from KES 70,000 for a 1.5m x 1.5m x 1.5m dryer with a capacity of 40-50kgs. Prices can go up to KES 120,000 for larger passive units (e.g., 2m x 5m x 2m with 100-130kgs capacity).

Medium Solar dryers

Can be more costly but offer greater capacity and efficient solar drying in Kenya.

From KES 150,000 – KES 175,000 for a 3m x 3m x 2m dryer.

KES 818,000 – KES 824,000 for large sizes (8m x 24m and 8m x 30m).

Hybrid Solar Dryers

Hybrid solar dryers are between KES 320,000 to KES 700,000, depending on size and drying capacity in Kenya .

Materials for Constructing a solar Drying Structure

Structure: Galvanized steel or treated timber are common. Galvanized steel is rust-free, durable, and easy to clean, making it a popular choice for commercial dryers.

Covering: UV-treated greenhouse polythene sheet (200 microns thickness) with waterproof nature is ideal. The UV nature prevents burning of produce by strong UV rays, while waterproof ability prevents rehydration of food.

Solar Drying Shelves: made by stainless steel mesh and covered with insect nets for proper airflow around the produce. These are often stacked to maximize drying capacity.

Insect Nets: UV-treated heavy-gauge insect nets are crucial at air inlets and outlets to prevent pests from contaminating the produce.

Heat Absorbent Material (Dam Liner): a heat-absorbing and releasing dam liner can be used to line the floor, reducing temperature fluctuations between day and night.

Considerations for Proper Solar Dryer Installation in Kenya

- Site Selection: Choose a location with maximum sun exposure throughout the day, away from shading by buildings or trees. Good ventilation and accessibility for loading and unloading are also important.

- Orientation: The dryer should be in an area with no trees or buildings to enhance air and sunlight access.

- Ventilation: Essential to ensure continuous removal of moist air. Passive dryers rely on strategically placed vents, while active dryers use fans.

- Modularity and Scalability: Many designs allow for expansion or customization based on increasing drying needs.

High Value Crops to Preserve by Solar Drying in Kenya

Solar drying is suitable for a wide range of agricultural products, helping farmers add value and reduce waste. In Kenya, commonly solar-dried harvests include:

- Fruits: Mangoes, bananas (often for flour), pineapples, papayas, berries, apples. Dried fruits make excellent snacks and can fetch premium prices.

- Vegetables: Tomatoes (for paste or flakes), onions, garlic, capsicum, traditional vegetables (e.g., kales, spinach), mushrooms.

- Grains and Legumes: Maize, beans, peas, rice, sorghum, millet. Proper drying prevents fungal growth and extends storage life.

- Herbs and Spices: Moringa, mint, rosemary, chili peppers, ginger, turmeric, coriander seeds, black pepper. Solar drying retains their volatile oils and medicinal properties.

- Root Crops: Cassava (for flour or industrial starch), arrowroots, sweet potatoes.

- Other Products: Coffee, tea leaves, pyrethrum, fish (e.g., omena), meat (beef, mutton).

Proper washing and slicing of fruits before drying in shelves is ideals to increase surface are for effective drying. Small grains and other products with small size are an exception as they can be dried without grinding.

Solar Dryer Construction Company in Kenya

Aqua Hub Kenya is Known for designing and constructing both passive and hybrid solar drying structures in Kenya. Our dryers include a range of sizes designed using galvanized steel and UV-treated polythene materials. We offer installation of solar dryers, hybrid solar powered dryers and training on how to use solar dryers for crop dehydration.