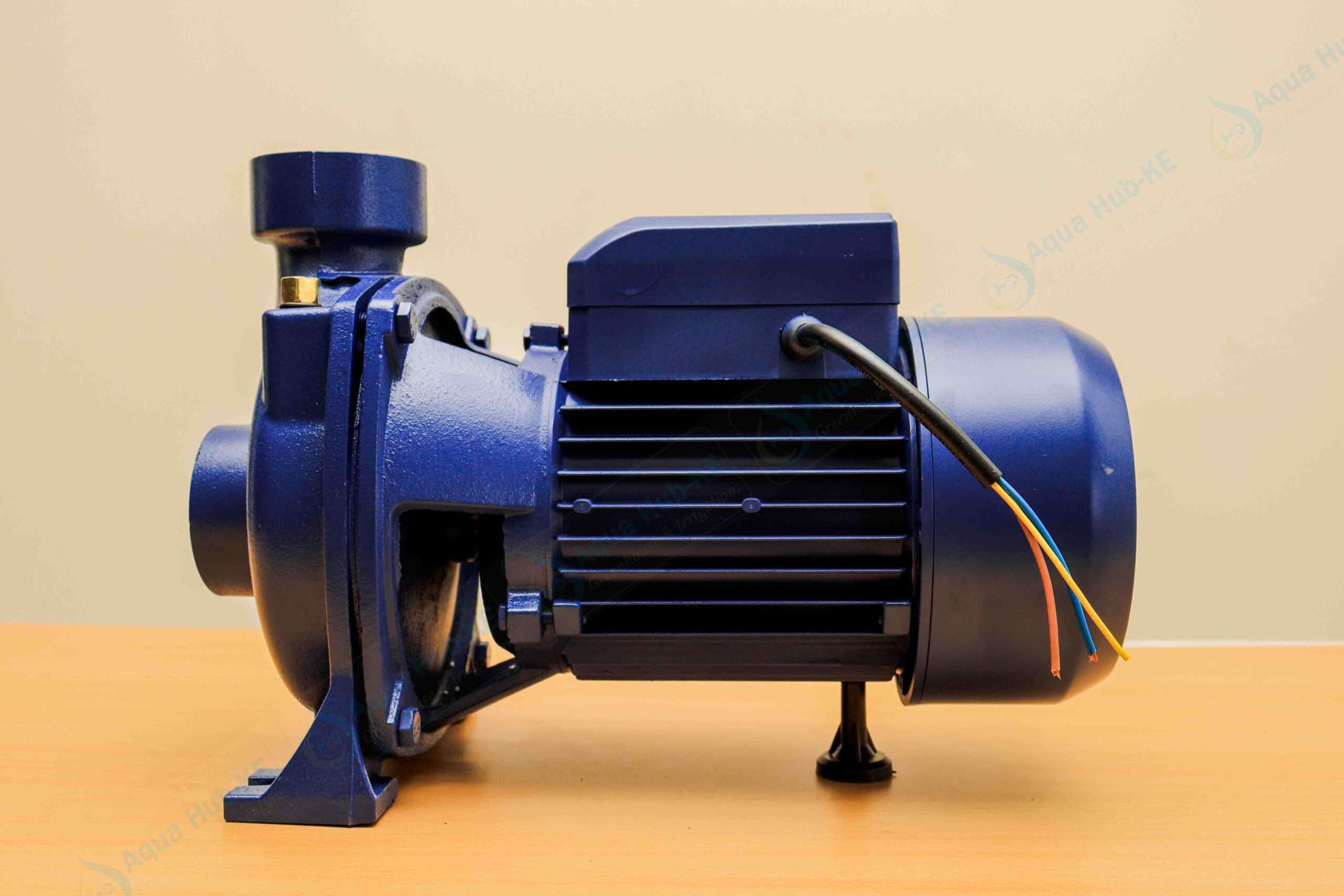

Centrifugal Pumps are common types of water pumps that use impeller rotation to move fluids. The impellers rotate and generate a centrifugal force which drives fluid into the delivery pipes.

Water or fluid enters through the axis of the impellers and is forced into the pump outlet by the high swirling force of the impellers.

Parts of a Centrifugal Pump

Impellers

Impellers are the main part of a centrifugal pump. It normally connects to an impeller which works by rotating it.

The fluid enters the pump via the axis of the impeller and leaves through the gap between the gaps between the vanes.

Pump Casing

The purpose of the pump casing is to guide the fluid flow into the impeller, control its direction and speed before discharge, and restrict the fluid flow from the inlet.

Shaft

The part made of stainless steel that holds and protects the impeller.

Shaft Sleeve

It is the casing of the shaft that is threaded to position the impeller correctly onto the shaft and protect the shaft.

Why Centrifugal Pumps are Preferable Options

Centrifugal pumps have a wide range of options and sizes to choose from. They deliver high flow rates of water at deliberately low-pressure rates. Energy consumption is also considerably low compared to other pump types.

Centrifugal pumps can also work in remote areas where electricity is out of reach. Fuel-operated types are the most reliable ones for rural areas.

Another good thing about them is their durability since they are made of strong metal casing and parts.

Types of Centrifugal Pumps

They are available in different types each suitable for use in specific fluid supply purposes.

Close Coupled Centrifugal Pumps

The motor is mounted together with the pump on one shaft. Not ideal for heavy-duty applications due to small bearing sizes.

Long Coupled Centrifugal Pumps

These types are designed with a pump and motor mounted on separate shafts connected by a coupling. Preferable for heavy-duty water and fluid supply applications.

Magnetic Drive Pumps

Works with magnets and eliminates the use of seals. One advantage is the low friction, and wear and tear. It makes them suitable for pumping flammable fluids such as petrol or diesel.

Mechanical Seal Centrifugal Pumps

They have body casing that prevents the fluid from leaking. These types are good for industrial applications due to their firm seal connection.

Vertical inline pumps

Types of centrifugal pumps that have the shaft and body casing designed to stand vertically. They operate while installed in an upright position.

Horizontal pumps

Centrifugal pumps with the shafts placed in a horizontal shape in between the bearings.

Multistage Pumps

Pumps with the design of more than one impeller to generate the high pressure required to move fluids. They are suitable for pumping water or fluids for a long distance.

Single-stage Pumps

Centrifugal pumps that have one impeller. They produce large flow rates in small pressure capabilities.

Do you need to learn more; Call 0790719020

How to Choose Centrifugal Pumps

Factors to consider for choosing centrifugal pumps are limited to application, size, and power source.

Application

The intended use of the centrifugal pump determines the type you will need. Whether heavy-duty or light applications suitable options are available.

Type of pump

Your water needs will dictate the type of pump, you need. As per the size or requirements of your project, you will consider whether a single-stage or multi-stage is suitable.

Size

It is essential to look at the size of the pump to determine whether it can handle the workload.

Pump Coupling

Centrifugal pump coupling is another factor to consider. Depending on the use intended, the coupling or spacing between the motor and pump matters.

Power Source

Choose a pump that suits you according to the power source it operates with. If you have no access to electricity, go for fuel-powered pumps.

For help in choosing an ideal pump; Call 0790719020.

Applications of Pumps

The pumps have a wide range of utilities including a supply of less viscous fluids such as water, oil, sewage waste, and industrial chemicals.

Common applications are agriculture for water supply, moving domestic water, and drawing clean or sewage water.

Domestic applications may require pumps to avail water including animal needs, cooking, garden, and lawn uses.

Buy Pumps from Aqua Hub Kenya

We among the best pump suppliers in Kenya and East Africa with surplus options for centrifugal, and other pump types.

Various sizes are available as per the needs of your applications.

Find long-lasting water pump solutions at unbelievable prices at our shops today.

Call 0790719020.